When producing whole food supplements or superfood powders, the raw materials must, of course, be of the highest quality. However, if the drying method is substandard, it can ruin a whole food supplement or superfood powder, no matter how good the raw materials were initially.

Drying superfoods or whole foods

There are three drying methods professionally used by manufacturers worldwide. However, Innate Response and MegaFood are the only ones using a fourth method, the so-called Refractance Window Drying method. Let us first look at the other three drying methods that are used by all companies in the world producing whole food supplements or superfoods.

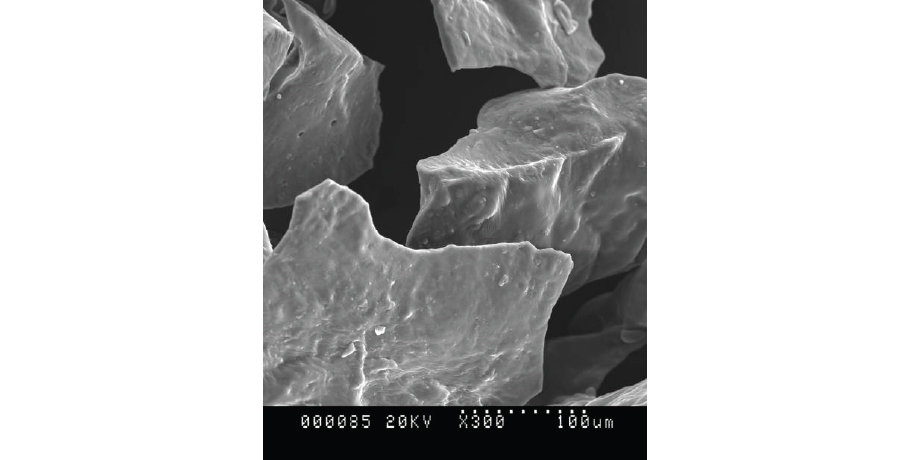

Drum-drying – not a good method

Drum drying involves pressing a vegetable, berry, herb, or fruit puree between two heated rollers rotating inward. The rollers maintain a temperature of approximately 150 degrees Celsius. The puree is exposed to extreme heat, degrading its color, phytonutrients, and micronutrients. As the microscopic image shows, the structure of a puree dried using drum drying is irregular and damaged.

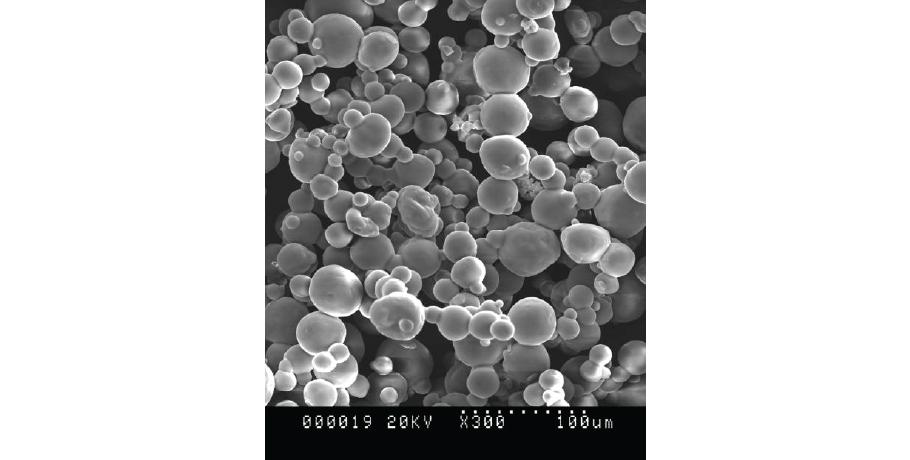

Spray-drying – not a good method

Spray drying involves spraying a vegetable, berry, herb, or fruit puree into a chamber filled with hot gases that evaporate the liquid part of the puree while droplets of dried material are collected in a container. The chamber temperature is extremely high, between 150–160 degrees Celsius. Similar to drum drying, this method degrades the color, phytonutrients, and micronutrients. As the microscopic image shows, the structure of a puree dried using spray drying is very porous with spherical microstructures, reducing the raw material's shelf life and making it prone to oxidation.

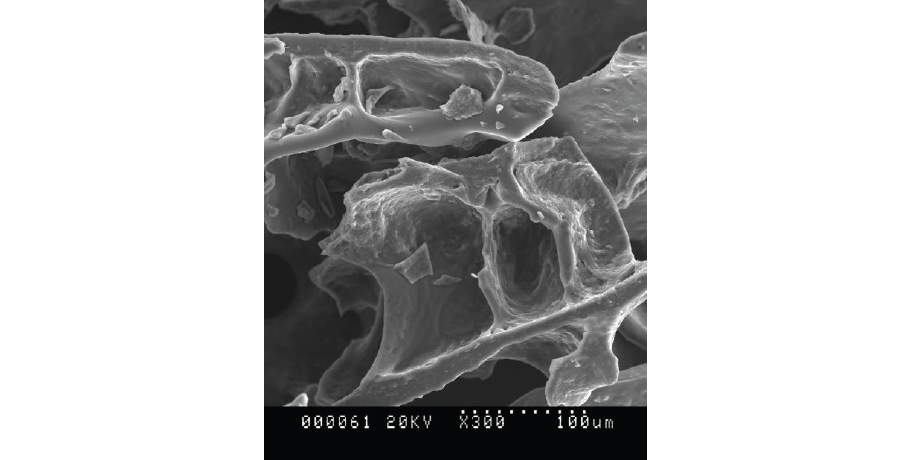

Freeze-drying – a somewhat better method

Freeze-drying involves quickly freezing the puree to about -50 to -80 degrees Celsius. A vacuum is then applied, causing the water to sublimate, i.e., transition directly from solid to gas without passing through the liquid phase. The process takes a long time, up to 32 hours, which makes micronutrients more likely to be lost during drying. It is also not uncommon for chemicals to be applied before freezing the raw material, although this is not always the case. As the microscopic image shows, the structure of a puree dried using freeze-drying is extremely porous and fragile, making it sensitive and more likely to lose nutrients.

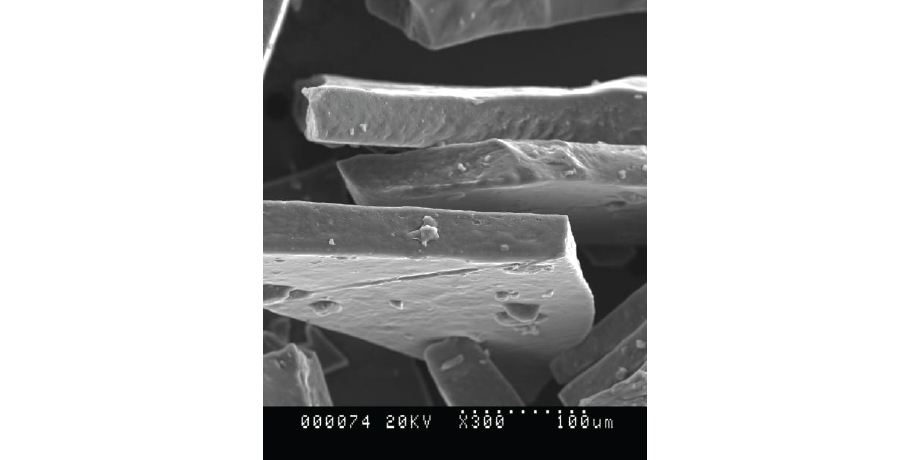

Refractance Window Drying – the best method

Innate Response and MegaFood use a fourth drying method, Refractance Window Drying, for the majority of their raw materials. For a few raw materials, freeze-drying is used. Refractance Window Drying is the gentlest method available on the market today, as the raw material is never heated above 42 degrees Celsius. The raw material is exposed to very low temperatures for a very short time. Unlike other methods, Refractance Window Drying does not involve high pressure or the use of chemicals. The raw material is placed on a microfilm and then dried with steam. The steam is then removed, and Refractance Window Drying regulates the moisture in the raw material, automatically stopping the process when the exact moisture level is achieved. The moisture level is very low, but sensitive micronutrients are not damaged by overly harsh drying methods. Under a microscope, a puree dried using Refractance Window Drying shows a uniform, non-porous structure, as the image illustrates. This results in significantly longer shelf life and reduces the risk of oxidation and free radical formation compared to all other drying methods. The final product lasts longer, resists oxidation and degradation better, and, most importantly, retains color, phytonutrients, and micronutrients. Studies on the method show that the retention of vitamins, minerals, enzymes, and phytochemicals is significantly higher when using Refractance Window Drying compared to other drying methods. To date, Refractance Window Drying is the absolute gentlest drying method in the world.

Why doesn’t everyone use Refractance Window Drying?

As always, it comes down to money. Other drying machines cost between approximately 40,000–250,000 dollars, which is a lot of money. A second-hand Refractance Window Dryer from 2006 in the U.S., which also has old patents, costs 750,000 dollars. Innate Response and MegaFood have four brand-new Refractance Window Dryers. Very few companies in the world are willing to spend over a million dollars on just one drying machine, let alone more than four million dollars.

The sad reality is that regardless of the drying method used, manufacturers can still label their products as whole food or superfood powders. Unfortunately, the drying method is often overlooked by many health food manufacturers and sellers. However, the drying method is just as important as the quality of the raw material and other parts of the production process, such as quality and safety testing in laboratories. A perfectly cultivated organic raw material can be ruined and lose many of its valuable properties due to the drying method used. How a raw material is dried is almost never mentioned on the label.